Exporting Premium Bitumen

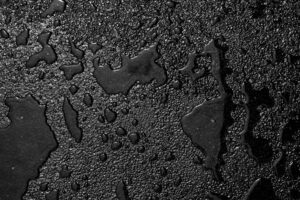

Hermes Refinery: Exporting Premium Bitumen Worldwide. Hermes Refinery, a leading name in Iran’s oil industry, has established itself as a premier exporter of high-quality bitumen.

Leveraging advanced technology and a commitment to excellence, Hermes Refinery exports various grades of bitumen to markets around the globe. This article delves into the types of bitumen produced, the refinery’s capabilities, and its global reach.

Types of Bitumen Produced by Hermes Refinery

Hermes Refinery produces a wide range of bitumen grades to meet diverse industrial needs. The primary types include:

- Penetration Grade Bitumen: Commonly used in road construction, this type is classified based on its hardness. Grades include 40/50, 60/70, and 80/100, each suitable for different climatic conditions.

- Viscosity Grade Bitumen: Known for its stable performance in varying temperatures, viscosity grades such as VG10, VG20, VG30, and VG40 are ideal for hot mix asphalt applications.

- Oxidized Bitumen: This type is produced by blowing air through penetration grade bitumen, making it suitable for roofing and waterproofing.

Quality and Standards

Hermes Refinery adheres to stringent quality control measures to ensure its bitumen meets international standards.

The refinery’s bitumen undergoes rigorous testing for properties such as specific gravity, penetration, softening point, ductility, and flashpoint, ensuring consistency and reliability in every batch.

Global Export Strategy

Hermes Refinery’s strategic location and robust logistics network enable it to export bitumen efficiently to various regions, including:

- Asia: Significant markets include India, China, and Southeast Asia, where rapid infrastructure development drives demand for high-quality bitumen.

- Middle East and Africa: Countries in these regions benefit from Hermes’ competitive pricing and reliable supply chain.

- Europe: The refinery meets the stringent quality requirements of European markets, providing bitumen for road construction and industrial applications.

- Americas: Hermes Refinery has established a presence in North and South America, catering to the growing infrastructure needs.

Sustainability and Innovation

Hermes Refinery is committed to sustainability and innovation. The refinery employs cutting-edge technology to minimize environmental impact and maximize resource efficiency. By converting oil sludge into valuable products, Hermes not only prevents waste but also contributes to a cleaner environment.

Customer-Centric Approach

Customer satisfaction is at the core of Hermes Refinery’s operations. The company offers tailored solutions to meet specific requirements, ensuring timely delivery and exceptional service. Hermes’ dedicated team works closely with clients to provide technical support and ensure the optimal performance of its bitumen products.

Hermes Refinery stands out as a global leader in bitumen production and export. With a diverse range of high-quality bitumen grades, a commitment to sustainability, and a customer-centric approach, Hermes Refinery is well-positioned to meet the growing demands of the global market. Whether for road construction, industrial applications, or waterproofing, Hermes’ bitumen products deliver unmatched performance and reliability.

Top Buyers of Hermes Refinery’s Bitumen

Hermes Refinery, a leading bitumen producer in Iran, exports its high-quality bitumen to various countries across the globe. Based on the available data, the top buyers of Hermes Refinery’s bitumen include:

1. China

China is a significant importer of bitumen from Iran, driven by its extensive infrastructure projects and road construction activities. The country’s rapid urbanization and development initiatives make it a key market for Hermes Refinery.

2. India

India is another major buyer of Hermes Refinery’s bitumen. The country’s ongoing infrastructure development, including the construction of highways and urban roads, fuels the demand for high-quality bitumen. India’s import value for bitumen is substantial, reflecting its critical role in the market.

3. France

France is one of the top European importers of bitumen, including from Hermes Refinery. The country’s infrastructural needs and maintenance of road networks contribute to its significant import volumes.

4. Southeast Asian Countries

Countries in Southeast Asia, such as Indonesia, are also important markets for Hermes Refinery. These nations are investing heavily in infrastructure, leading to increased demand for bitumen.

5. Middle Eastern and African Nations

Several Middle Eastern and African countries import bitumen from Hermes Refinery. These regions benefit from the refinery’s competitive pricing and reliable supply chain. Notable importers include various African nations and countries in the Persian Gulf region.

6. CIS Countries

The Commonwealth of Independent States (CIS) countries, including Uzbekistan and Turkmenistan, are significant importers of Hermes Refinery’s bitumen. These countries leverage regional trade agreements and logistical advantages to source bitumen from Iran.

Logistics and Packing of Bitumen

Transporting and packaging bitumen is a complex process due to its highly viscous nature and the necessity to maintain it at specific temperatures. Efficient logistics and appropriate packaging are crucial to ensure the integrity and usability of bitumen upon delivery. Here, we explore the various methods of transporting and packaging bitumen, highlighting their advantages and disadvantages.

Bitumen Transport Methods

1. Bitumen Drums

– **Description**: Bitumen drums are typically made of steel and come in various sizes, such as 55-gallon (208 L), 58-gallon (220 L), and 66-gallon (250 L) drums.

– Advantages:

– Easy to handle and store.

– Suitable for long-distance transportation.

– Allows for maintaining a large inventory.

– Disadvantages:

– Drums can leak or break if mishandled.

– Manual decanting is labor-intensive and inefficient.

– Environmental concerns due to disposal of used drums.

2. Bitumen Containers (Bitutainers™)

– Description: Specialized containers designed for transporting bitumen in liquid form, allowing it to cool during transit.

– Advantages:

– Flexible and cost-effective for various quantities.

– Secure and reliable, preventing leakage or spillage.

– Efficient full product discharge, minimizing waste.

– Disadvantages:

– Requires storage space for containers.

– Initial capital or lease costs.

– Containers need to be returned to the loading point, adding to logistics costs.

3. Bulk Shipments

– Description: Transporting bitumen in large quantities using specialized tanker trucks, railcars, or ships with insulated and heated tanks.

– Advantages:

– Economical for large-scale operations.

– Minimizes contamination risks.

– Suitable for continuous supply to large projects.

– Disadvantages:

– Requires specialized handling equipment and facilities.

– High capital investment and operating costs.

– Limited flexibility in delivery locations.

4. Flexitank Containers

– Description: Large, flexible bags made from polyethylene and polypropylene, installed in standard 20-foot shipping containers.

– Advantages:

– Cost-effective and maximizes container space.

– Single-use, reducing contamination risks.

– Environmentally friendly, as materials are recyclable.

– Quick filling and unloading, enhancing operational efficiency.

– Disadvantages:

– Single-use nature may not be suitable for all logistics setups.

– Requires careful handling to avoid damage during transit.

Bitumen Packaging Methods

1. New Steel Drums

– Description: Traditional packaging method using steel drums of various sizes.

– Pros:

– Robust and widely available.

– Suitable for long-term storage.

– Cons:

– High environmental impact due to disposal issues.

– Potential for leakage and contamination.

2. Jumbo Bags

– Description: Flexible multi-layer bags with high resistance, used for transporting bitumen as solids.

– Pros:

– Reduces bitumen waste by approximately 3%.

– Environmentally friendly and easy to handle.

– Cons:

– Requires specific handling equipment.

– Not suitable for all types of bitumen.

3. Poly Bags

– Description: Bags made from durable materials, used for transporting solid bitumen.

– Pros:

– Affordable and easy to handle.

– Minimizes wastage, as inner lining is consumable.

– Cons:

– Requires careful handling to avoid damage.

– May not be suitable for all logistics scenarios.

Exporting Premium Bitumen

Visit our blog to see more products